Riker strives to be a world-class supplier of exhaust, air intake systems and custom formed tube products. We serve the Heavy-Duty Vehicle, Off-Road Equipment and Industrial Supply Markets with integrity and open communication, partnerships with our customers, employee involvement, and supplier participation. Our associates are committed to continuous improvement in solving customer problems, the quality of our products and services, productivity and our profitability. We are dedicated to exceeding the expectations of and developing partnerships with our customers and suppliers, providing our associates an opportunity for personal growth, caring for our environment, and being good corporate citizens of the communities where we live and work.

Riker strives to be a world-class supplier of exhaust, air intake systems and custom formed tube products. We serve the Heavy-Duty Vehicle, Off-Road Equipment and Industrial Supply Markets with integrity and open communication, partnerships with our customers, employee involvement, and supplier participation. Our associates are committed to continuous improvement in solving customer problems, the quality of our products and services, productivity and our profitability. We are dedicated to exceeding the expectations of and developing partnerships with our customers and suppliers, providing our associates an opportunity for personal growth, caring for our environment, and being good corporate citizens of the communities where we live and work.

- IATF 16949 Quality Management System

- Adherence to Automotive Industry Action Group (AIAG)

- ISO 14001 Environmental Management System

Riker Products Inc. is committed to implement continual improvement of the QMS and EMS.

Ensuring quality through:

- Development, production, and delivery of the highest quality product to ensure customer satisfaction, and

- Increasing productivity and profitability.

Protecting the environment through:

- Preservation of natural resources,

- Providing a safe and clean working environment for our employees and community,

- Prevention of pollution, and

- Compliance to legal and other requirements.

- ISO 4405, ISO 4406, per customer specifications

- Pressure Testing (air & hydro)

- Dye-penetrant Testing

• Bosch • Caterpillar • CNH • Navistar • Oshkosh

• Sullair • Tenneco • Volvo • And More…

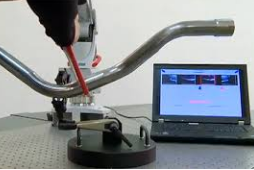

Riker maintains a state-of-the-art, on-site quality lab to enable capable processes that yield predictable results, part after part.

Riker maintains a state-of-the-art, on-site quality lab to enable capable processes that yield predictable results, part after part.

Specific strengths include part cleanliness testing and Coordinate Measuring Machine (CMM) tube inspection systems linked directly to our CNC tube bending equipment for instant corrective machine data adjustments. This closed-loop, automated tuning system removes waste and guesswork when working with various material grades, bend radii and other variants.

Our confidence in these systems is reinforced by our product warranty that is extended to every part we make.